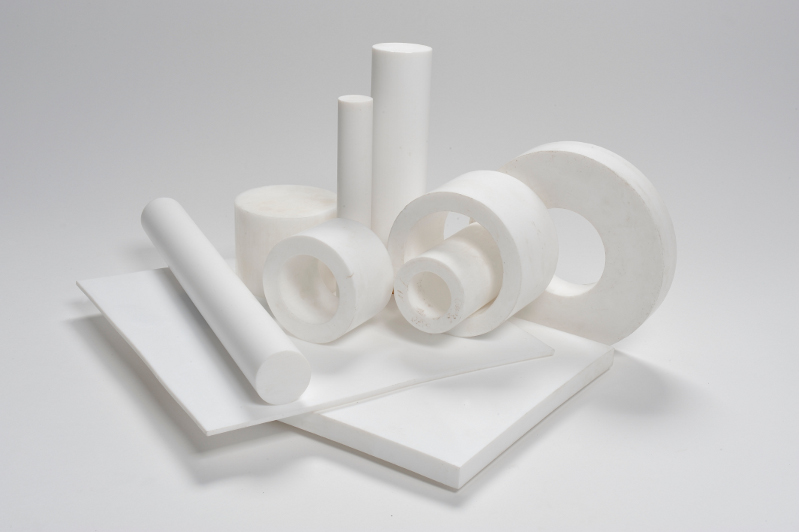

PTFE, or polytetrafluoroethylene, is a synthetic fluoropolymer that is known for its excellent resistance to heat, chemicals, and corrosion. It is often used in a wide range of industrial and commercial applications, including as a non-stick coating on cookware, in electrical insulation, and in sealing and gasketing applications. In addition to pure PTFE, there are also a variety of PTFE filled materials that are available. These materials are created by adding fillers to the PTFE resin during the manufacturing process, which can improve specific properties of the material for different applications. Some common types of PTFE filled materials include: Glass-filled PTFE: This material is created by adding glass fibers to PTFE, which improves its strength and stiffness while maintaining its chemical resistance. Carbon-filled PTFE: Carbon-filled PTFE contains carbon particles, which improve its conductivity and reduce its coefficient of friction. Bronze-filled PTFE: This material contains bronze powder, which improves its wear resistance and thermal conductivity. Graphite-filled PTFE: Graphite-filled PTFE is often used in high-temperature applications, as it has excellent thermal conductivity and can withstand temperatures up to 500°C. Some common applications of PTFE and PTFE filled materials include: Seals and gaskets: PTFE's chemical resistance and low coefficient of friction make it ideal for use in sealing and gasketing applications, especially when combined with fillers like glass or bronze. Electrical insulation: PTFE's excellent dielectric properties make it a popular choice for electrical insulation applications, such as wire and cable coatings. Bearings and bushings: PTFE's low coefficient of friction and high wear resistance make it a popular choice for bearings and bushings in industrial machinery. Non-stick coatings: PTFE's non-stick properties make it ideal for use as a coating on cookware, bakeware, and other food processing equipment. High-temperature applications: PTFE filled materials, such as graphite-filled PTFE, are often used in high-temperature applications, such as furnace linings and insulation.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.rubberoringbengaluru.com/mysore/latest-update/ptfe-or-polytetrafluoroethylene-is-a-synthetic-f/35

PTFE, or polytetrafluoroethylene, is a synthetic f...

2023-03-25T09:52:30

PTFE, or polytetrafluoroethylene, is a synthetic fluoropolymer that is known for its excellent resistance to heat, chemicals, and corrosion. It is often used in a wide range of industrial and commercial applications, including as a non-stick coating on cookware, in electrical insulation, and in sealing and gasketing applications. In addition to pure PTFE, there are also a variety of PTFE filled materials that are available. These materials are created by adding fillers to the PTFE resin during the manufacturing process, which can improve specific properties of the material for different applications. Some common types of PTFE filled materials include: Glass-filled PTFE: This material is created by adding glass fibers to PTFE, which improves its strength and stiffness while maintaining its chemical resistance. Carbon-filled PTFE: Carbon-filled PTFE contains carbon particles, which improve its conductivity and reduce its coefficient of friction. Bronze-filled PTFE: This material contains bronze powder, which improves its wear resistance and thermal conductivity. Graphite-filled PTFE: Graphite-filled PTFE is often used in high-temperature applications, as it has excellent thermal conductivity and can withstand temperatures up to 500°C. Some common applications of PTFE and PTFE filled materials include: Seals and gaskets: PTFE's chemical resistance and low coefficient of friction make it ideal for use in sealing and gasketing applications, especially when combined with fillers like glass or bronze. Electrical insulation: PTFE's excellent dielectric properties make it a popular choice for electrical insulation applications, such as wire and cable coatings. Bearings and bushings: PTFE's low coefficient of friction and high wear resistance make it a popular choice for bearings and bushings in industrial machinery. Non-stick coatings: PTFE's non-stick properties make it ideal for use as a coating on cookware, bakeware, and other food processing equipment. High-temperature applications: PTFE filled materials, such as graphite-filled PTFE, are often used in high-temperature applications, such as furnace linings and insulation.

2023-03-25T09:52:30

Keywords

- use

- wire

- heat

- Seals

- 500°C

- gaskets

- fillers

- variety

- sealing

- bakeware

- Bearings

- cookware

- friction

- bushings

- strength

- addition

- stiffness

- chemicals

- pure PTFE

- corrosion

- PTFE resin

- wide range

- common types

- glass fibers

- temperatures

- bronze powder

- popular choice

- cable coatings

- furnace linings

- low coefficient

- carbon particles

- stick properties

- Glass-filled PTFE

- Carbon-filled PTFE

- Bronze-filled PTFE

- Non-stick coatings

- common applications

- chemical resistance

- specific properties

- Graphite-filled PTFE

- high wear resistance

- industrial machinery

- excellent resistance

- manufacturing process

- PTFE filled materials

- different applications

- gasketing applications

- polytetrafluoroethylene

- commercial applications

- synthetic fluoropolymer

- high-temperature applications

- excellent thermal conductivity

- excellent dielectric properties

- other food processing equipment

- electrical insulation applications

Search on this site

Have any question or need any business consultation?

Have any question or need any business consultation?

Contact UsEastern Rubber & Engineering Enterprises

Submit Your Enquiry